by Queener Law | Mar 19, 2016 | Tennessee, Trucking Accident

Truck accidents were on a steady decline several years ago. Unfortunately, this positive trend has sharply reversed, as laws have became more lenient. Of course, their sheer size makes driving around big rigs dangerous, but when truck drivers experience fatigue, the results can be deadly.

Staggering Statistics

In 2009, truck-related deaths were at an all-time low, and 2,983 truck accidents were responsible for 3,380 deaths. In 2013, the last year that these finalized statistics were available, over 3,500 wrecks resulted in nearly 4,000 deaths. In Tennessee alone, there were 126 truck-related accidents in 2013. Trucking accidents are responsible for one in every seven highway deaths in this country.

According to the U.S. Department of Transportation, driver fatigue is the leading cause of trucking accidents. Of course, there are plenty of additional factors that contribute to large vehicle crashes, but it’s wise for everyone on the road to keep an eye out for drowsy drivers.

Safety Laws

Over the past few years, there have been some modifications to trucking safety laws, but they may be short-lived. In 2013, Federal law reduced the maximum hours a trucker can work each week to 70, from 82. Drivers who hit their limit must take a 34 hour rest period before starting a new work week. This rest-session must include two periods between 1 and 5 am. Drivers may not drive for more than 11 hours each day, which must include a 30 minute break.

As helpful as these laws may be to reducing trucking accident deaths, many trucking industry officials are citing a decline in profits as their reasoning behind their push for a repeal of these regulations. They have also pushed for changes to the 80,000 pound haul limit, along with length regulations that mandate that no truck can haul a trailer over 28 feet. If they get their way, a double-trailer rig could carry trailers that are 33 feet long, making the truck as long as an eight-story building is tall.

Some groups, like the Federal Motor Carrier Safety Administration, are pushing for additional safety measures. Since 2008, they have recommended that drivers get screened for sleep apnea, a condition that is closely linked to sleep deprivation. Unfortunately, due to the high cost of testing, they have recently backed off.

As updates to the laws continue to be debated, safety advocates and truck accident attorneys urge that drivers use caution on the roads.

by Queener Law | Mar 18, 2016 | Auto Accident, Tennessee

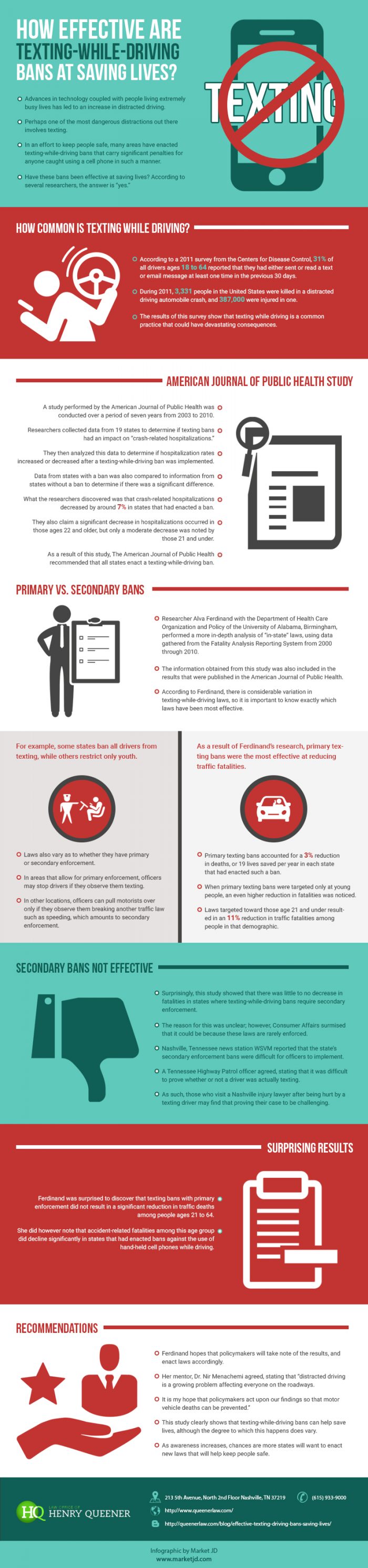

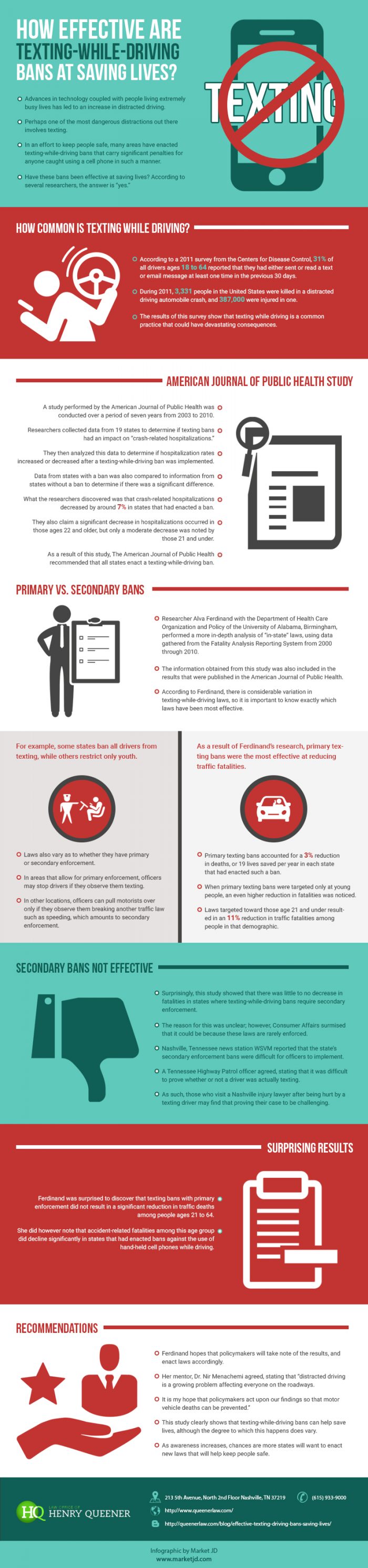

Advances in technology coupled with people living extremely busy lives has led to an increase in distracted driving. Perhaps one of the most dangerous distractions out there involves texting. In an effort to keep people safe, many areas have enacted texting-while-driving bans that carry significant penalties for anyone caught using a cell phone in such a manner. Have these bans been effective at saving lives? According to several researchers, the answer is “yes.”

How Common is Texting While Driving?

According to a 2011 survey from the Centers for Disease Control, 31 percent of all drivers ages 18 to 64 reported that they had either sent or read a text or email message at least one time in the previous 30 days. During 2011, 3,331 people in the United States were killed in a distracted driving automobile crash, and 387,000 were injured in one. The results of this survey show that texting while driving is a common practice that could have devastating consequences.

American Journal of Public Health Study

A study performed by the American Journal of Public Health was conducted over a period of seven years from 2003 to 2010. Researchers collected data from 19 states to determine if texting bans had an impact on “crash-related hospitalizations.” They then analyzed this data to determine if hospitalization rates increased or decreased after a texting-while-driving ban was implemented. Data from states with a ban was also compared to information from states without a ban to determine if there was a significant difference.

What the researchers discovered was that crash-related hospitalizations decreased by around 7% in states that had enacted a ban. They also claim a significant decrease in hospitalizations occurred in those ages 22 and older, but only a moderate decrease was noted by those 21 and under. As a result of this study, The American Journal of Public Health recommended that all states enact a texting-while-driving ban.

Primary vs. Secondary Bans

Researcher Alva Ferdinand with the Department of Health Care Organization and Policy of the University of Alabama, Birmingham, performed a more in-depth analysis of “in-state” laws, using data gathered from the Fatality Analysis Reporting System from 2000 through 2010. The information obtained from this study was also included in the results that were published in the American Journal of Public Health.

According to Ferdinand, there is considerable variation in texting-while-driving laws, so it is important to know exactly which laws have been most effective. For example, some states ban all drivers from texting, while others restrict only youth.

Laws also vary as to whether they have primary or secondary enforcement. In areas that allow for primary enforcement, officers may stop drivers if they observe them texting. In other locations, officers can pull motorists over only if they observe them breaking another traffic law such as speeding, which amounts to secondary enforcement.

As a result of Ferdinand’s research, primary texting bans were the most effective at reducing traffic fatalities. Primary texting bans accounted for a three percent reduction in deaths, or 19 lives saved per year in each state that had enacted such a ban. When primary texting bans were targeted only at young people, an even higher reduction in fatalities was noticed. Laws targeted toward those age 21 and under resulted in an 11 percent reduction in traffic fatalities among people in that demographic.

Secondary Bans not Effective

Surprisingly, this study showed that there was little to no decrease in fatalities in states where texting-while-driving bans require secondary enforcement. The reason for this was unclear; however, Consumer Affairs surmised that it could be because these laws are rarely enforced.

Nashville, Tennessee news station WSVM reported that the state’s secondary enforcement bans were difficult for officers to implement. A Tennessee Highway Patrol officer agreed, stating that it was difficult to prove whether or not a driver was actually texting. As such, those who visit a Nashville injury lawyer after being hurt by a texting driver may find that proving their case to be challenging.

Surprising Results

Ferdinand was surprised to discover that texting bans with primary enforcement did not result in a significant reduction in traffic deaths among people ages 21 to 64. She did however note that accident-related fatalities among this age group did decline significantly in states that had enacted bans against the use of hand-held cell phones while driving.

Recommendations

Ferdinand hopes that policymakers will take note of the results, and enact laws accordingly. Her mentor, Dr. Nir Menachemi agreed, stating that “distracted driving is a growing problem affecting everyone on the roadways. It is my hope that policymakers act upon our findings so that motor vehicle deaths can be prevented.”

This study clearly shows that texting-while-driving bans can help save lives, although the degree to which this happens does vary. As awareness increases, chances are more states will want to enact new laws that will help keep people safe.

by Queener Law | Mar 17, 2016 | Tennessee, Trucking Accident

Washington, DC – April 25, 2016—This week the United States Senate began deliberations on a new budget for the Department of Transportation. Though the purpose of the bill is to fund both the Department of Transportation and HUD, there are provisions in the budget that are deeply troubling to groups lobbying for safer roads.

Groups opposing the bill point to several key provisions that indicate capitulation to the trucking industry, and increase the risk of accidents. The most controversial provision changes the current calculation on hours of service restarts for drivers.

Current rules state that drivers are required to take a 34 hour break once they reach their hours of service cap for a seven day period. The break reduces driver fatigue, the leading cause of semi truck accidents. The new bill would permanently roll back hours of service restarts to pre-2011 levels, a decision which significantly reduces the downtime between restarts and eliminates mandatory 30 minute breaks for long-haul drivers.

The trucking industry and its lobbyists argue the reduction in restart periods is vital to maintain profitability for trucking companies and higher wages for drivers. Profits for trucking companies have remained flat since the start of the Great Recession, despite the recent drop in the price of diesel. If trucking companies are unable to increase the turnover rate of their trucks through more frequent deliveries, American Trucking Associations believe there will be a collapse of the transportation industry.

Henry Queener, a semi truck accident lawyer in Nashville, sees proposed changes to the hours of service in the Department of Transportation budget as a clear step in the wrong direction. “We’ve seen a steady increase in the number of fatal semi truck accidents, as well as continued increases in the economic cost of accidents. Putting tired drivers on the road, and encouraging drivers to miss hour of service restarts, will make all of our roads a lot less safe”.

The budget debate is certain to be contentious, especially after the trucking industry suffered setbacks with proposed speed limiters and a Congressional refusal to increase the size and weight of trucks.

by Queener Law | Mar 16, 2016 | Tennessee, Trucking Accident

New rules make it easier to hold truckers accountable for how many hours they are behind the wheel. This will cut down on the number off accidents caused by sleepy drives, officials hope.

A new proposal would require truckers to electronically record their time behind the wheel. This has been mandated by federal law late in 2015, but Tennessee has not yet officially adopted the measure. When there is an accident with a big truck, there are often fatalities. Studies have shown one reason trucks get into accidents is tired or sleepy drivers, an this rule is aimed at making that happen less often.

In 2013 rules were passed by the Tennessee Legislature that limit how much time a trucker can drive, and it required certain amounts of time to be taken off. Recording the hours electronically takes it a step further by making verification easier.

A Nashville truck accident lawyer said he welcomed the changes.

“Ultimately we want to see fewer accidents and fewer deaths on the highways,” Henry Queener of the Queener Law Office in Nashville said. “Holding truckers accountable will help keep them off the road when they are drowsy. It might also protect them from being abused by their companies, so it benefits everyone.”

According to an Associated Press story, truckers have kept paper logs in the past, but new technology will keep track of engine hours, vehicle movement, miles driven, and location, which will make it hard for anyone to work around the system. For years paper records have been kept, but it was easy to keep two sets of records, or to even just put in wrong information.

Truckers often face a double edged sword of sorts. The temptation is great at times to grab another load. They may not feel tired, think they can handle it and the money is tempting. Also sometimes employers give hard deadlines and drivers are behind the wheel longer than they should be. Either situation can make them sleepy and unsafe behind the wheel. If you are in an accident contact a truck accident lawyer in Tennessee.

by Queener Law | Mar 14, 2016 | Colorado, Kentucky, Tennessee, Trucking Accident

Despite the attention that distracted driving and large truck accidents has had in the media over the last few years, and federal laws which are geared towards reducing the number of accidents due to distracted driving, recent investigations reveal that distracted driving still remains a problem for truck drivers. In fact, distracted driving plays a role in an estimated 8 percent of large truck accidents each year. While 8 percent doesn’t seem like a number of much magnitude, when an individual considers that there are approximately 4,000 fatalities due to large truck accidents in the United States each year, and an estimated 284 injuries each day caused by accidents with big rigs, 8 percent is actually a large number.

Since safety advocates first began evaluating the issue of distracted driving and the big rigs, the use of cellphones has been a major focus. In 2012, a federal law went into effect banning the use of handheld cellphones while operating a commercial truck. The law includes interstate truck drivers and bus drivers as well as drivers who transport “placardable quantities of hazardous materials”.

The Dangers of Using Cellphones While Driving

Countless commercial vehicle drivers still use their cellphones regularly while driving, but the effects of doing so can be catastrophic.

- Research shows that commercial motor vehicle operators who use their cellphones to text while driving are 23 times more likely to become involved in an accident or safety critical event than drivers who did not text and drive.

- Truck drivers who use their cellphones to place or receive calls and performed other operations that required dialing were 6 times more likely to experience an event than those who avoided such cellphone usage.

- Drivers who reach for a cellphone or other object in such a manner that interferes with a safe driving position are approximately 7 times more likely to become involved in a safety critical event.

Drivers typically take their eyes off of the road for between 3.8 and 4.6 seconds when texting or dialing. During that short period of time a commercial vehicle traveling approximately 55 mph. will cover more ground than a football field- an estimated 300 ft.

While using handheld devices is strictly prohibited, using them in a hands-free manner is generally acceptable. Any hands-free device needs to be within close proximity to the trucker. Additionally, the federal regulations regarding cellphones do not apply to devices used for dispatching unless texting is involved.

The Penalties for Driving and Using Cellphones

For those who are caught texting or using handheld cellphones while operating a motor vehicle, the penalties can be severe.

- Drivers can face fines of up to $2,750

- Second and subsequent offenses can result in the truck driver being placed out of service for up to 120 days.

- Violations will have a negative impact on the employer’s Safety Measurement System rating.

- Employers can be fined up to $11,000 if they require or knowingly allow their truck drivers to text or use hand-held cellphones while operating a commercial vehicle.

- Violations of the law are considered to be serious traffic violations and penalties are taken with consideration of the existing Federal Motor Carrier Safety Administration guidelines.

In addition to the above stated penalties, drivers who violate the law could be subject to whatever punishments their employer wishes to dish out in accordance to their own policies. Since many companies have policies that are similar to those regulations set forth by the federal law, and truckers who use handheld cellphones while driving are at a higher risk for accidents, they are like lawsuits waiting to happen. Termination of employment upon violation of the law is common.

Although many states have not set their own laws regarding commercial vehicles and cellphone usage, truckers should be aware that they are still required to follow the regulations set forth by the federal law when traveling interstate, regardless of the state they are in.

Other Forms of Distracted Driving Among Truck Drivers

Unfortunately, using cellphones while driving is not the only form of distracted driving that effects truckers and their risk of accidents. The unique lifestyle that goes along with trucking brings with it a strong temptation, and sometimes necessity, to perform other tasks while driving. Two of the more common distractions among truckers are:

- Eating or Drinking: Due to strict deadlines, many truckers don’t have the time to pull over and eat when they are hungry. Therefore, they often grab something to go and eat on the road to make deliveries on time.

- Reading Maps or GPS Screens: Since truckers often travel in areas that they are unfamiliar with, it is an extremely common practice for them to take their eyes off of the road to look at directions.

by Queener Law | Mar 14, 2016 | Colorado, Kentucky, Tennessee, Trucking Accident

A truck driver’s health directly impacts their ability to operate a big rig truck safely. One often overlooked issue that affects a truckers ability to safely do their job are respiratory conditions.

Sleep Apnea

Nearly one third of truck drivers have sleep apnea. One problem is that the condition is under diagnosed. Persons with the condition stop breathing for short periods when they are asleep. This can occur up to 400 times a night. Since sleep apnea occurs when the person is asleep, many people don’t realize they have it unless a partner mentions it. Recent studies show that truckers who have untreated sleep apnea have five times more crashes than other truck drivers.

This makes it impossible for the person to get a restful nights sleep. As a result they are fatigued during the day, even if they have gotten enough hours of sleep. Falling asleep isn’t the only risk associated with the disorder. It can also affect concentration and memory, which can also increase the truckers risk of an accident.

Current Regulations and Reporting

Truckers have to undergo a health examination once every two years. They are not currently required to check for signs or risk factors of sleep apnea, however. The truckers are asked one question about a possible sleep disorder on the questionnaire that they are required to fill out. The issue is many don’t recognize symptoms like loud snoring or daytime fatigue as being out of the ordinary, and many that do realize their condition don’t admit it out of fear of loosing their job.

Diagnosis and Treatment

For most people, sleep apnea is a very treatable condition. However, they must be diagnosed first. While there are signs and risk factors to be taken into account, the only way to diagnose sleep apnea for certain is to do a sleep study where the patient is observed and monitored while they sleep. Sleep apnea is generally treated with a CPAP mask, but oral appliances and surgery can be options for some.

A trucking accident attorney can use untreated sleep apnea as a way to prove that the trucker was liable for the accident. While it isn’t a hard and fast rule, there are a growing number of cases where a trucking accident attorney recovered for their client on the basis of sleep apnea.