by Queener Law | Mar 14, 2016 | Colorado, Kentucky, Tennessee, Trucking Accident

Despite the attention that distracted driving and large truck accidents has had in the media over the last few years, and federal laws which are geared towards reducing the number of accidents due to distracted driving, recent investigations reveal that distracted driving still remains a problem for truck drivers. In fact, distracted driving plays a role in an estimated 8 percent of large truck accidents each year. While 8 percent doesn’t seem like a number of much magnitude, when an individual considers that there are approximately 4,000 fatalities due to large truck accidents in the United States each year, and an estimated 284 injuries each day caused by accidents with big rigs, 8 percent is actually a large number.

Since safety advocates first began evaluating the issue of distracted driving and the big rigs, the use of cellphones has been a major focus. In 2012, a federal law went into effect banning the use of handheld cellphones while operating a commercial truck. The law includes interstate truck drivers and bus drivers as well as drivers who transport “placardable quantities of hazardous materials”.

The Dangers of Using Cellphones While Driving

Countless commercial vehicle drivers still use their cellphones regularly while driving, but the effects of doing so can be catastrophic.

- Research shows that commercial motor vehicle operators who use their cellphones to text while driving are 23 times more likely to become involved in an accident or safety critical event than drivers who did not text and drive.

- Truck drivers who use their cellphones to place or receive calls and performed other operations that required dialing were 6 times more likely to experience an event than those who avoided such cellphone usage.

- Drivers who reach for a cellphone or other object in such a manner that interferes with a safe driving position are approximately 7 times more likely to become involved in a safety critical event.

Drivers typically take their eyes off of the road for between 3.8 and 4.6 seconds when texting or dialing. During that short period of time a commercial vehicle traveling approximately 55 mph. will cover more ground than a football field- an estimated 300 ft.

While using handheld devices is strictly prohibited, using them in a hands-free manner is generally acceptable. Any hands-free device needs to be within close proximity to the trucker. Additionally, the federal regulations regarding cellphones do not apply to devices used for dispatching unless texting is involved.

The Penalties for Driving and Using Cellphones

For those who are caught texting or using handheld cellphones while operating a motor vehicle, the penalties can be severe.

- Drivers can face fines of up to $2,750

- Second and subsequent offenses can result in the truck driver being placed out of service for up to 120 days.

- Violations will have a negative impact on the employer’s Safety Measurement System rating.

- Employers can be fined up to $11,000 if they require or knowingly allow their truck drivers to text or use hand-held cellphones while operating a commercial vehicle.

- Violations of the law are considered to be serious traffic violations and penalties are taken with consideration of the existing Federal Motor Carrier Safety Administration guidelines.

In addition to the above stated penalties, drivers who violate the law could be subject to whatever punishments their employer wishes to dish out in accordance to their own policies. Since many companies have policies that are similar to those regulations set forth by the federal law, and truckers who use handheld cellphones while driving are at a higher risk for accidents, they are like lawsuits waiting to happen. Termination of employment upon violation of the law is common.

Although many states have not set their own laws regarding commercial vehicles and cellphone usage, truckers should be aware that they are still required to follow the regulations set forth by the federal law when traveling interstate, regardless of the state they are in.

Other Forms of Distracted Driving Among Truck Drivers

Unfortunately, using cellphones while driving is not the only form of distracted driving that effects truckers and their risk of accidents. The unique lifestyle that goes along with trucking brings with it a strong temptation, and sometimes necessity, to perform other tasks while driving. Two of the more common distractions among truckers are:

- Eating or Drinking: Due to strict deadlines, many truckers don’t have the time to pull over and eat when they are hungry. Therefore, they often grab something to go and eat on the road to make deliveries on time.

- Reading Maps or GPS Screens: Since truckers often travel in areas that they are unfamiliar with, it is an extremely common practice for them to take their eyes off of the road to look at directions.

by Queener Law | Mar 14, 2016 | Colorado, Kentucky, Tennessee, Trucking Accident

A truck driver’s health directly impacts their ability to operate a big rig truck safely. One often overlooked issue that affects a truckers ability to safely do their job are respiratory conditions.

Sleep Apnea

Nearly one third of truck drivers have sleep apnea. One problem is that the condition is under diagnosed. Persons with the condition stop breathing for short periods when they are asleep. This can occur up to 400 times a night. Since sleep apnea occurs when the person is asleep, many people don’t realize they have it unless a partner mentions it. Recent studies show that truckers who have untreated sleep apnea have five times more crashes than other truck drivers.

This makes it impossible for the person to get a restful nights sleep. As a result they are fatigued during the day, even if they have gotten enough hours of sleep. Falling asleep isn’t the only risk associated with the disorder. It can also affect concentration and memory, which can also increase the truckers risk of an accident.

Current Regulations and Reporting

Truckers have to undergo a health examination once every two years. They are not currently required to check for signs or risk factors of sleep apnea, however. The truckers are asked one question about a possible sleep disorder on the questionnaire that they are required to fill out. The issue is many don’t recognize symptoms like loud snoring or daytime fatigue as being out of the ordinary, and many that do realize their condition don’t admit it out of fear of loosing their job.

Diagnosis and Treatment

For most people, sleep apnea is a very treatable condition. However, they must be diagnosed first. While there are signs and risk factors to be taken into account, the only way to diagnose sleep apnea for certain is to do a sleep study where the patient is observed and monitored while they sleep. Sleep apnea is generally treated with a CPAP mask, but oral appliances and surgery can be options for some.

A trucking accident attorney can use untreated sleep apnea as a way to prove that the trucker was liable for the accident. While it isn’t a hard and fast rule, there are a growing number of cases where a trucking accident attorney recovered for their client on the basis of sleep apnea.

by Queener Law | Mar 11, 2016 | Tennessee, Trucking Accident

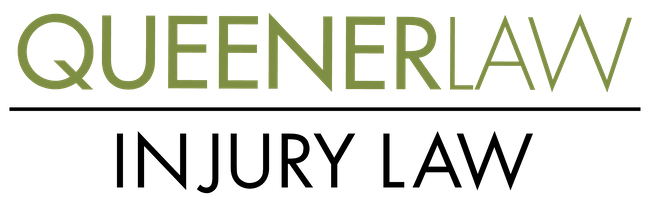

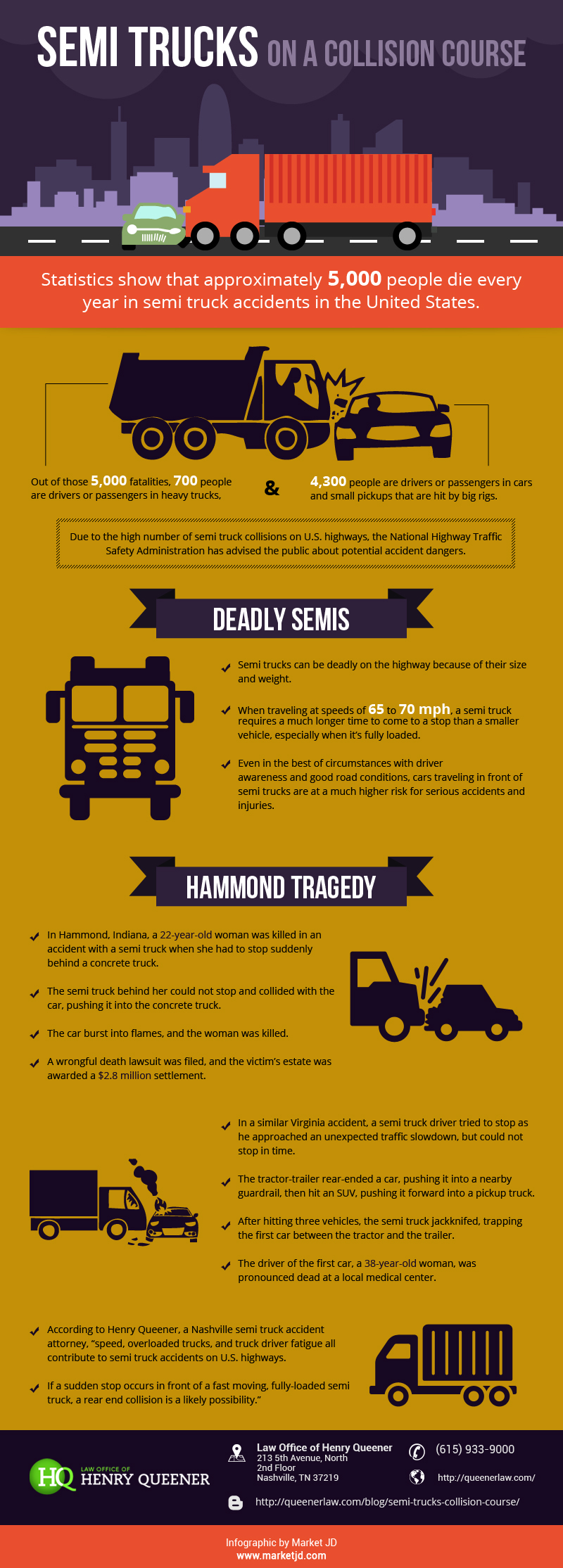

Statistics show that approximately 5,000 people die every year in semi truck accidents in the United States. Out of those 5,000 fatalities, 700 people are drivers or passengers in heavy trucks, and 4,300 people are drivers or passengers in cars and small pickups that are hit by big rigs. Due to the high number of semi truck collisions on U.S. highways, the National Highway Traffic Safety Administration has advised the public about potential accident dangers.

Semi trucks can be deadly on the highway because of their size and weight. When traveling at speeds of 65 to 70 mph, a semi truck requires a much longer time to come to a stop than a smaller vehicle, especially when it’s fully loaded. Even in the best of circumstances with driver awareness and good road conditions, cars traveling in front of semi trucks are at a much higher risk for serious accidents and injuries.

In Hammond, Indiana, a 22-year-old woman was killed in an accident with a semi truck when she had to stop suddenly behind a concrete truck. The semi truck behind her could not stop and collided with the car, pushing it into the concrete truck. The car burst into flames, and the woman was killed. A wrongful death lawsuit was filed, and the victim’s estate was awarded a $2.8 million settlement.

In a similar Virginia accident, a semi truck driver tried to stop as he approached an unexpected traffic slowdown, but could not stop in time. The tractor-trailer rear-ended a car, pushing it into a nearby guardrail, then hit an SUV, pushing it forward into a pickup truck. After hitting three vehicles, the semi truck jackknifed, trapping the first car between the tractor and the trailer. The driver of the first car, a 38-year-old woman, was pronounced dead at a local medical center.

According to Henry Queener, a Nashville semi truck accident attorney, “speed, overloaded trucks, and truck driver fatigue all contribute to semi truck accidents on U.S. highways. If a sudden stop occurs in front of a fast moving, fully-loaded semi truck, a rear end collision is a likely possibility.”

by Queener Law | Mar 11, 2016 | Tennessee, Trucking Accident

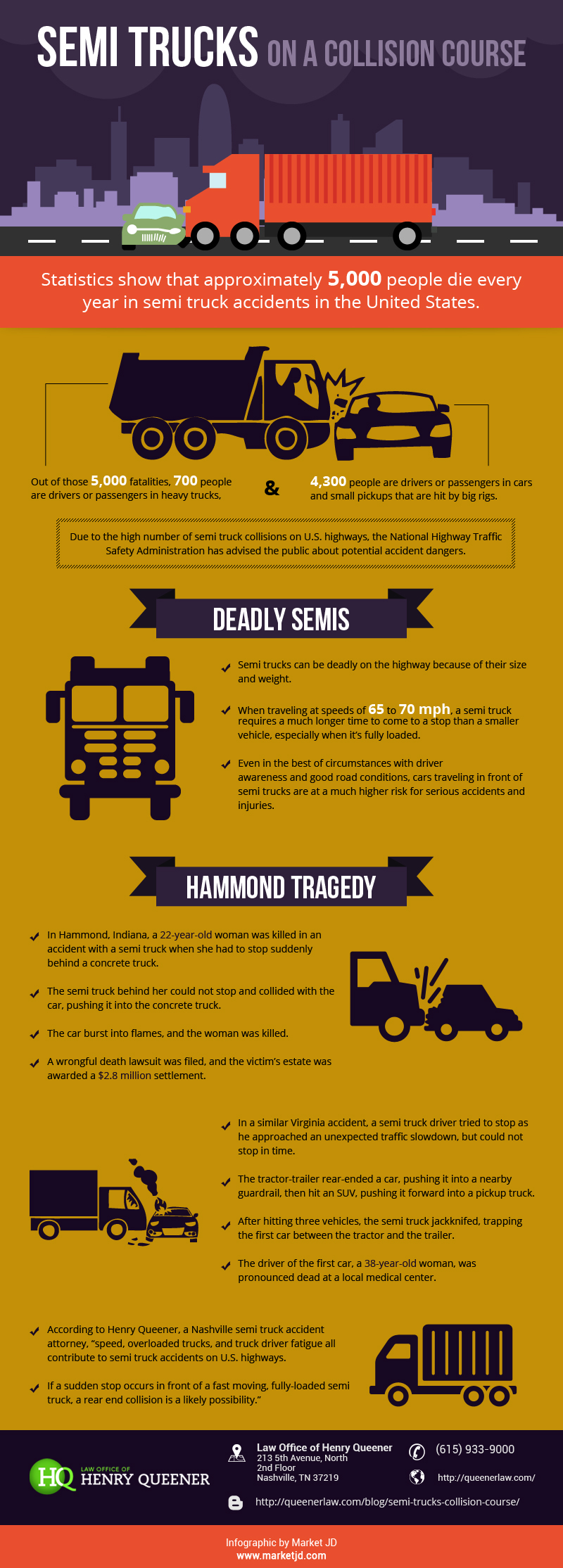

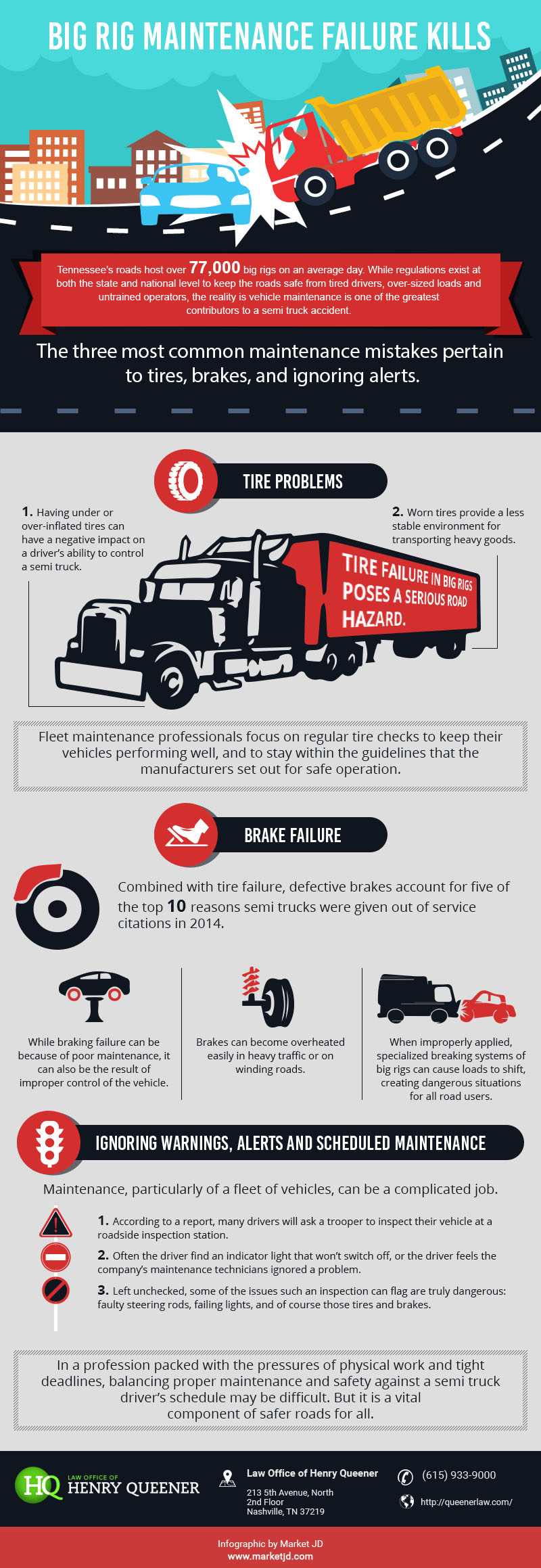

Tennessee’s roads host over 77,000 big rigs on an average day. While regulations exist at both the state and national level to keep the roads safe from tired drivers, over-sized loads and untrained operators, the reality is vehicle maintenance is one of the greatest contributors to a semi truck accident. Attorneys and law enforcement officials alike are increasingly aware of the vital role good maintenance plays in big rig safety on Tennessee’s roads. The three most common maintenance mistakes pertain to tires, brakes and ignoring alerts.

Tire problems

Tire failure in big rigs poses a serious road hazard. Having under or over-inflated tires can have a negative impact on a driver’s ability to control a semi truck. What’s more, worn tires provide a less stable environment for transporting heavy goods. Fleet maintenanceprofessionals focus on regular tire checks to keep their vehicles performing well, and to stay within the guidelines that the manufacturers set out for safe operation.

Brake failure

Combined with tire failure, defective brakes account for five of the top 10 reasons semi trucks were given out of service citations in 2014. Determining the root cause of braking failure can occupy a lot of space on a semi truck accident attorney’s desk. While braking failure can be because of poor maintenance, it can also be the result of improper control of the vehicle. Brakes can become overheated easily in heavy traffic or on winding roads. Also, when improperly applied, specialized breaking systems of big rigs can cause loads to shift, creating dangerous situations for all road users.

Ignoring warnings, alerts and scheduled maintenance

Maintenance, particularly of a fleet of vehicles, can be a complicated job. According to a report in the Chattanooga Times Free Press last December, many drivers will ask a trooper to inspect their vehicle at a roadside inspection station, because there’s a niggling indicator light that won’t switch off or the driver feels the company’s maintenance technicians ignored a problem. Left unchecked, some of the issues such an inspection can flag are truly dangerous: faulty steering rods, failing lights, and of course those tires and brakes.

In a profession packed with the pressures of physical work and tight deadlines, balancing proper maintenance and safety against a semi truck driver’s schedule may be difficult. But it is a vital component of safer roads for all.

by Queener Law | Mar 8, 2016 | Colorado, Kentucky, Tennessee, Trucking Accident

On December 4, 2015, President Obama’s signature placed the Fixing America’s Surface Transportation (FAST) Act into law just a day after the House of Representatives passed the Act 83 to 16 in a race to beat the date of the expiration of the current funding extension. The impressive 1,300 page legislation is the first long term solution to settling highway and funding issues in more than a decade. The five year Bill will provide $305 billion in funding for roads, bridges and mass transit.

Additionally, the Act will include a number of regulatory reforms on the trucking industry. On Tuesday, December 1, 2015, the Executive Vice President of the Owner-Operator Independent Drivers Association, Todd Spencer stated that he believed the Act was a positive compromise.

Effects of the Fast Act on the Trucking Industry

At first glance, most of the provisions that were proposed by both sides appeared to have a fighting chance. Some of the items that were on the trucking industry’s wish list and that of safety advocates were omitted from the final Bill, however.

- The trucking industry had asked that federal law allow truckers as young as 18 to operate trucks across state lines. While advocates for the provision claimed that doing so would solve the issue of a long time shortage of truck drivers, safety advocates who opposed the provision cited studies that suggest that younger, less experienced drivers are at a significantly higher risk of being involved in a trucking accident. Instead of including the provision in the Bill, the Act sets up a controlled study that is to be conducted by the FMCSA to determine the benefits and safety impacts of allowing young drivers to join the long haulers.

- While some lawmakers and lobbyists were pushing for more lenient regulations with regards to maximum truck weights and sizes, no measures to change federal weight and size regulations were included in the Bill. Those in favor were asking for weight limits of 91,000 pounds and increased tandem truck length maximums to be raised to 33 feet.

- Some safety advocates had asked that the Bill include language that required that brokers, shippers and others to hire only carriers with satisfactory safety ratings. Since an estimated 400,000 small trucking companies and owner-operators are not rated by the FMCSA, doing so would have put a damper on the business opportunities for these groups. The Hiring Standards provision, therefore, was not included.

- It had been proposed that the current minimum liability insurance limit be raised from its current amount of $750,000. Instead, the Act requires that an investigation be completed that will help determine if the minimum should be raised in the future.

A number of new regulations that will affect the trucking industry did make it into the Act, however. Some of the more important on the list include:

- Much needed CSA reform is in the near future. Until the faults of the program are evaluated and fixed, certain information will no longer be available to the public regarding carriers’ rankings. Some information, like violations and inspection data are stipulated to remain in public view.

- Drug testing in the trucking industry is destined to undergo change. Employers will now have the ability to use hair tests in lieu of urine tests to make overall testing results that report average usage more accurate. Hair testing will be a powerful tool that helps carriers keep habitual drug users off the nation’s roads. Within one year of the Bill’s enactment, the federal Department of Health and Human Services (DHHS) is to provide established guidelines for hair testing.

- While more lax regulations pertaining to driver rest periods and maximum work hours did not make it into the Bill, the Act requires that the FMCSA conduct a study that evaluates how delays during loading and delivery impact a driver’s schedule, performance and pay. The study will also reveal how detention times effect the flow of U.S. freight.

- The Bill requires that the FMCSA reform the rules that govern commercial driver’s license (CDL) issuance. The new law will allow military veterans who have experience operating large equipment that is comparable to heavy trucks to more easily obtain civilian truck driving jobs. It will also allow military veterans to use their experience that was obtained in the military to count towards required skills tests. The Bill will also allow military veterans to obtain their required medical certification from Veterans Affairs doctors rather than only from those in FMCSA’s National Registry of Medical Examiners.

- Tow truck drivers who are removing heavy trucks and other large equipment fromaccidents and emergency situations will now be exempt from federal weight limits on federal roads. The tow trucks must deliver their load to the nearest available repair center, however.

by Queener Law | Mar 5, 2016 | Tennessee, Trucking Accident

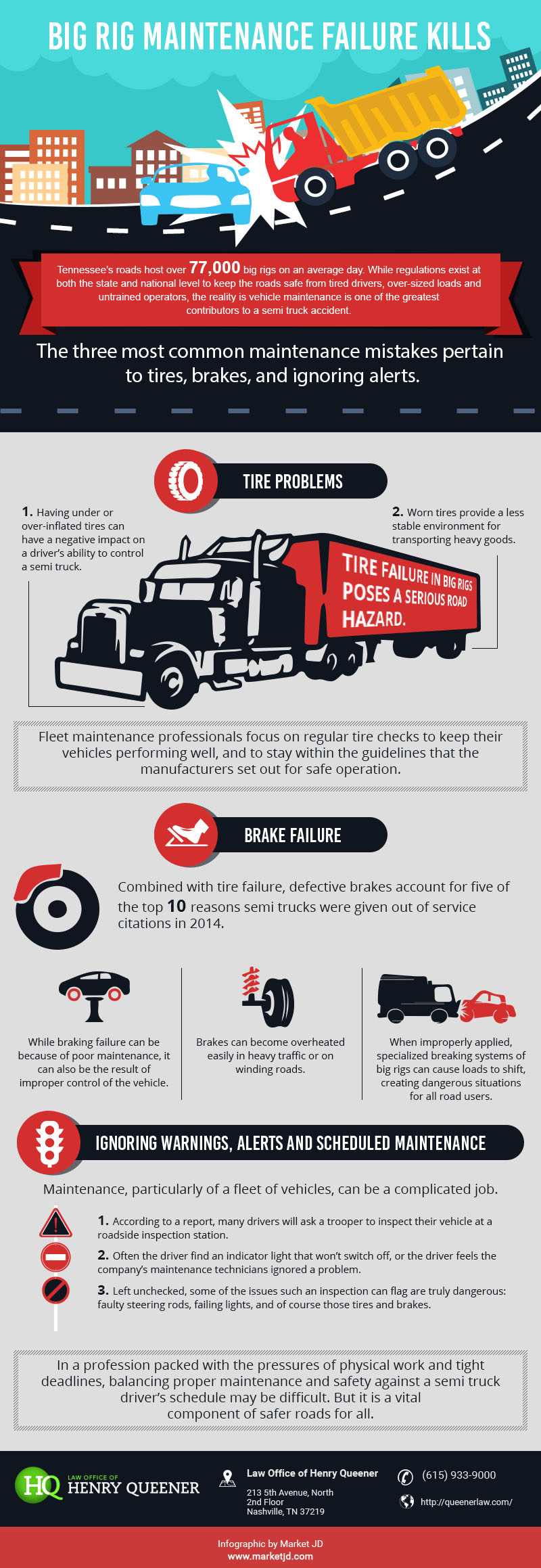

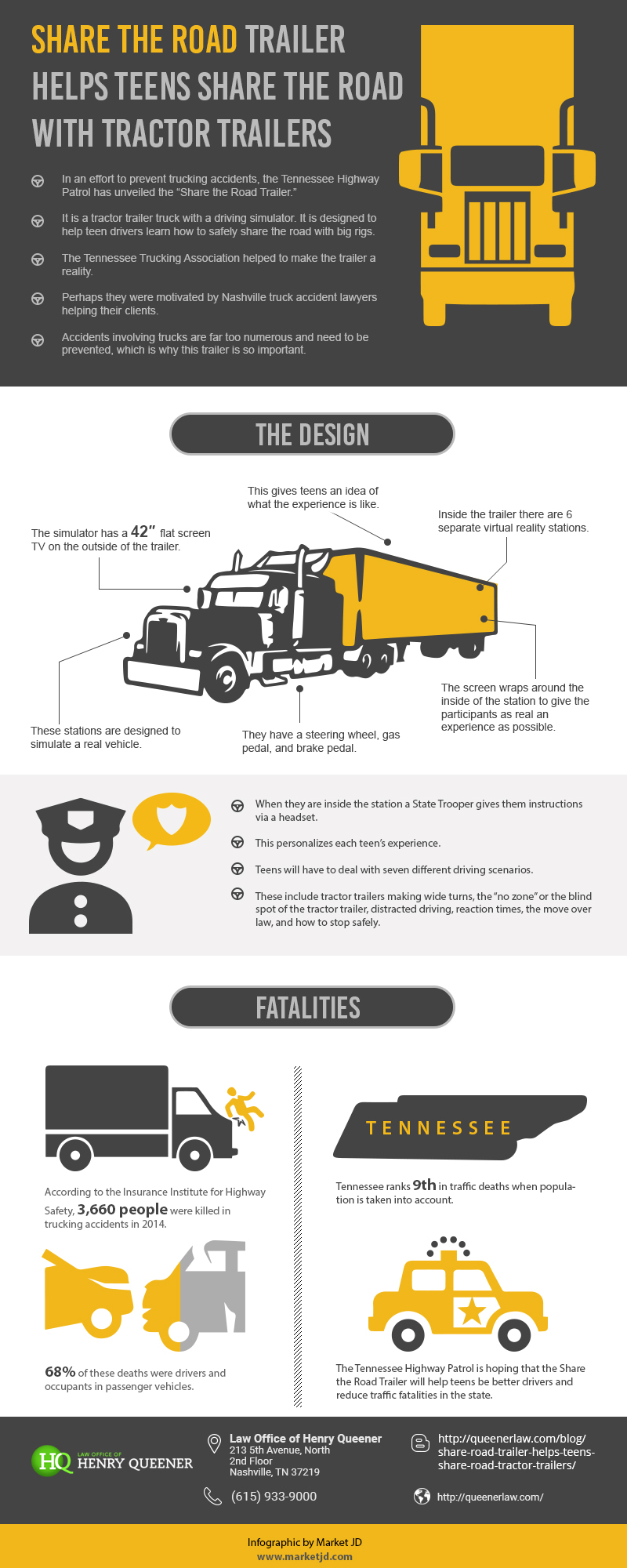

In an effort to prevent trucking accidents, the Tennessee Highway Patrol has unveiled the “Share the Road Trailer.” It is a tractor trailer truck with a driving simulator. It is designed to help teen drivers learn how to safely share the road with big rigs.

The Tennessee Trucking Association helped to make the trailer a reality. Perhaps they were motivated by Nashville truck accident lawyers helping their clients. Accidents involving trucks are far too numerous and need to be prevented, which is why this trailer is so important.

The simulator has a 42″ flat screen TV on the outside of the trailer. This gives teens an idea of what the experience is like. Inside the trailer there are 6 separate virtual reality stations. These stations are designed to simulate a real vehicle. They have a steering wheel, gas pedal, and brake pedal. The screen wraps around the inside of the station to give the participants as real an experience as possible.

When they are inside the station a State Trooper gives them instructions via a headset. This personalizes each teen’s experience. Teens will have to deal with seven different driving scenarios. These include tractor trailers making wide turns, what happens when they cut off a tractor trailer, the “no zone” or the blind spot of the tractor trailer, distracted driving, reaction times, the move over law, and how to stop safely.

According to the Insurance Institute for Highway Safety, 3,660 people were killed in trucking accidents in 2014. 68% of these deaths were drivers and occupants in passenger vehicles. Tennessee ranks ninth in traffic deaths when population is taken into account. The Tennessee Highway Patrol is hoping that the Share the Road Trailer will help teens be better drivers and reduce traffic fatalities in the state.